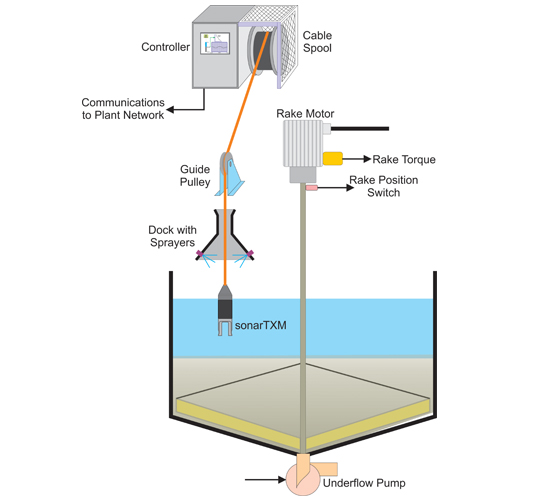

SteadyBed® Thickener Control System with SonarTXM® Technology

The SteadyBed® Thickener Control System controls the thickener discharge rate (underflow pump speed) based on the input parameters: mud bed height, rake torque, rake position and underflow density to produce consistent optimum performance of the thickener. Ideally a thickener should be operated at a mud bed height which maximises underflow density without exerting excessive torque on the rake mechanism.

A key component of the SteadyBed® Thickener Control System is the SonarTXM® sensor developed jointly with DannTech Process Instrumentation. It is a specialized, purposed designed, sensing device which has its own internal circuitry to conduct several types of measurements. The measurements are primarily ultrasound attenuation at one or more wavelengths to suit the mud characteristics. The sensor has some intelligence built-in to ensure reliable and repeatable continuous operational measurement of the mud level in thickeners and settling tanks. The time between measurements is designed to ensure that the measurement is done to avoid the rake movement.

Versions on offer:

SteadyBed® Portable Pro with SonarTXM® technology

Portable probe in durable case

SteadyBed® Auto with SonarTXM® technology

Probe fitted on drum reel for automatic measurement

SteadyBed® Thickener Control System with SonarTXM® technology

Probe fitted on drum reel for automatic measurement and full control of thickener underflow discharge