Slurry Dewatering and Filtration Solutions

- Ore, Water and Slurry Characterisation

- Design Data Generation – flocculation, thickening, filtration tests

- Equipment Sizing

- Dewatering Circuit Design for Greenfields applications

- Laboratory and Pilot Scale Studies

- Site Audits and On-Site Tests for optimisation of Brownfields operations

- Technical adjudication of dewatering equipment tenders

- SteadyBed® thickener control philosophy

Speciality Solutions towards Dry Tailings Disposal

- Beyond conventional de-watering, i.e. paste thickening, pressure filtration and hybrid systems

- Tailings rheology modification

- Determination of tailings bleed water limit upon deposition

- Amelioration of tailings for rehabilitation

Ore Geo-Metallurgy

- In Partnering with

- Full Ore Characterisation

- Data Generation for Geo-Metallurgical Modelling

- Prediction of slurry / tailings process behaviour

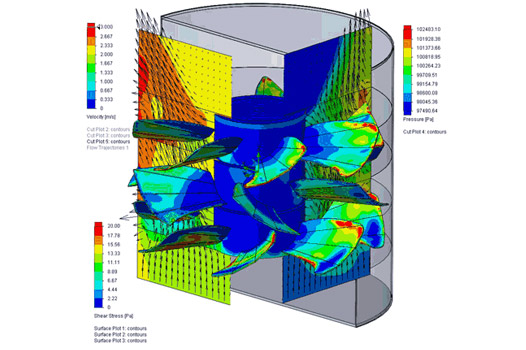

CFD Modelling

- In partnership with

- CFD modelling is one of the tools used by Vietti Slurrytec in the auditing of dewatering equipment and allows for cost effective solutions to optimise thickener operation and specify upgrades.